Underground mining tunnel ventilation is a crucial aspect of ensuring safety and efficiency in mining operations. Efficient ventilation systems are essential for maintaining air quality and providing breathable air to miners working deep underground. This article outlines the key requirements and standards that govern underground mining tunnel ventilation, focusing on their importance, design specifications, functional components, and maintenance protocols.

Importance of Tunnel Ventilation in Underground Mining

Purpose and Objectives

The primary purpose of tunnel ventilation in underground mining is to facilitate the circulation of fresh air while dissipating harmful gases generated by mining activities. Effective ventilation systems help to ensure that the atmosphere remains safe for workers, mitigating the risk of respiratory illnesses and accidents caused by explosive gases like methane. The objectives of tunnel ventilation extend to enhancing operational efficiency by controlling temperatures and humidity levels, thereby improving overall working conditions deep within the subterranean environment.

Historical Context

Historically, underground mining has presented significant hazards related to air quality and the breathing environment. As mining technology has evolved, so too have the methods and standards for ventilation. Early mining operations relied on natural ventilation processes, but as mines grew deeper and operations became more complex, the need for engineered ventilation systems became apparent. The transition to mechanized mining methods has necessitated advancements in ventilation techniques, resulting in more structured approaches to maintaining a healthy underground atmosphere.

Key Requirements for Effective Ventilation

Air Quality Standards

Air quality standards are paramount in the design of ventilation systems for underground mines. Regulations set forth by governing bodies, such as the Mine Safety and Health Administration (MSHA) and various international standards, stipulate permissible concentration levels of harmful gases, including carbon dioxide, carbon monoxide, and particulates. Continuous monitoring of air quality is necessary to ensure compliance with these standards, thereby protecting the health and safety of miners.

Ventilation System Design

The design of an underground mining ventilation system must meet specific requirements tailored to the unique challenges of the environment. Factors such as mine depth, layout, and the types of minerals being extracted influence design choices. An effective ventilation system integrates various elements such as main fans, auxiliary ventilation units, and well-placed intake and exhaust shafts to optimize airflow throughout the mine. Additionally, redundancy and flexibility are critical design considerations, allowing for adjustments and improvements as mining operations evolve.

Airflow Management

Proper airflow management is essential to ensure that fresh air reaches all areas of the mine while effectively removing stale air. This requires careful planning and execution of airflow networks that can adapt to the changing conditions of mining work. The velocity and direction of airflow must be controlled to prevent the accumulation of toxic gases and maintain a stable temperature. Engineers often utilize computational fluid dynamics modeling to predict airflow behaviors within the tunnels, further enhancing the overall efficiency of the ventilation system.

Monitoring and Maintenance Protocols

Regular Inspections

Regular inspections of the ventilation system are critical to ensure its continued effectiveness. Scheduled assessments help identify potential issues such as damage to fans, blockages in ducts, or inefficiencies in air distribution. These inspections should be comprehensive and adhere to established safety protocols. Documenting findings allows for the timely implementation of necessary repairs and modifications, which is vital for maintaining a safe working environment.

Sensor Technologies

The implementation of advanced sensor technologies facilitates continuous monitoring of air quality and system performance. Sensors can detect changes in gas concentrations, temperature variations, and airflow patterns, allowing for immediate responses to potential hazards. By integrating these technologies into the ventilation system, mines can achieve greater responsiveness to dynamic underground conditions, ultimately enhancing worker safety and operational efficiency.

Maintenance Procedures

Establishing robust maintenance procedures is key to ensuring the longevity and reliability of ventilation systems. Routine maintenance tasks include cleaning and servicing fans, inspecting ductwork, and checking the functionality of auxiliary equipment. Additionally, any changes in mining operations may necessitate reevaluation and adjustment of the ventilation strategy. Such proactive measures play an essential role in sustaining the effectiveness of tunnel ventilation while preventing potential failures.

Compliance with Safety Standards

International Guidelines

International guidelines play a pivotal role in regulating underground mining tunnel ventilation practices to ensure a safe working environment for miners. Organizations such as the International Council on Mining and Metals (ICMM) and the World Health Organization (WHO) have established comprehensive frameworks outlining air quality standards and ventilation requirements pertinent to mining operations. These guidelines advocate for implementing systematic ventilation strategies tailored to minimize worker exposure to hazardous gases, excessive heat, and dust. Adhering to these international guidelines not only promotes miner health and safety but also encourages the adoption of best practices across the global mining industry.

National Regulations

National regulations are essential in establishing specific requirements for ventilation systems within the jurisdiction of a country. In the United States, the Mine Safety and Health Administration (MSHA) enforces regulations mandating that mining companies implement effective ventilation systems capable of maintaining air quality standards. These regulations often dictate the monitoring frequency of airborne contaminants and identify the thresholds that must not be surpassed. Compliance with national regulations is crucial as it helps mitigate risks associated with inadequate ventilation, ultimately fostering a culture of safety within the mining sector.

Certification Processes

Certification processes ensure that equipment and methodologies used in underground mining tunnel ventilation are competent, safe, and compliant with both national and international standards. Various regulatory bodies and certificates, such as ISO certifications, evaluate ventilation systems, confirming that they meet rigorous performance criteria. These processes often involve thorough testing and inspection phases to validate the design, installation, and operational capabilities of ventilation systems. Achieving certification is vital not only for legal compliance but also for instilling confidence among stakeholders regarding the reliability and safety of mining operations.

Challenges and Future Directions

Technological Advances

Technological advances are shaping the future of underground mining tunnel ventilation by enhancing efficiency and safety measures. Innovations, such as smart ventilation systems equipped with artificial intelligence and machine learning, allow for real-time data analysis and adaptive airflow management, significantly improving air quality and reducing energy consumption. The integration of advanced modeling software enables engineers to simulate ventilation designs, leading to optimized layouts tailored to specific mine configurations and conditions. As technology continues to progress, it is expected that further enhancements in ventilation will contribute to the establishment of more resilient and safer mining environments.

Environmental Considerations

Environmental considerations are becoming increasingly important in the design and operation of underground mining tunnel ventilation systems. The impact of mining activities on surrounding ecosystems and communities necessitates the implementation of sustainable ventilation practices that reduce the carbon footprint. Efforts to achieve energy efficiency in ventilation systems contribute to lowering operational costs and minimizing adverse environmental effects. The future of tunnel ventilation is likely to involve greater emphasis on renewable energy sources and environmentally friendly technologies that align with global sustainability goals.

Training and Education

Training and education are fundamental components in ensuring that personnel responsible for underground mining tunnel ventilation are well-equipped with necessary skills and knowledge. Comprehensive training programs should encompass aspects of ventilation system design, maintenance, and monitoring, enabling mine operators to understand the importance of compliance with safety standards. Furthermore, ongoing education regarding emerging technologies and environmental considerations is essential for fostering a culture of continuous improvement within the mining industry. Adequately trained workers are better positioned to identify potential issues within ventilation systems, enhancing overall workplace safety and operational efficiency.

About Zongda Mining Equipment Co., Ltd.

Company Overview

Zongda Mining Equipment Co., Ltd. has established itself as a key player in the mining sector, specializing in the development and manufacturing of innovative ground support and ventilation solutions. With years of experience and expertise, the company has garnered a reputation for delivering high-quality products tailored to meet the diverse needs of clients in the mining industry. Zongda’s commitment to research and development ensures that it remains at the forefront of technological advancements, contributing to enhanced safety standards and operational performance within underground mining.

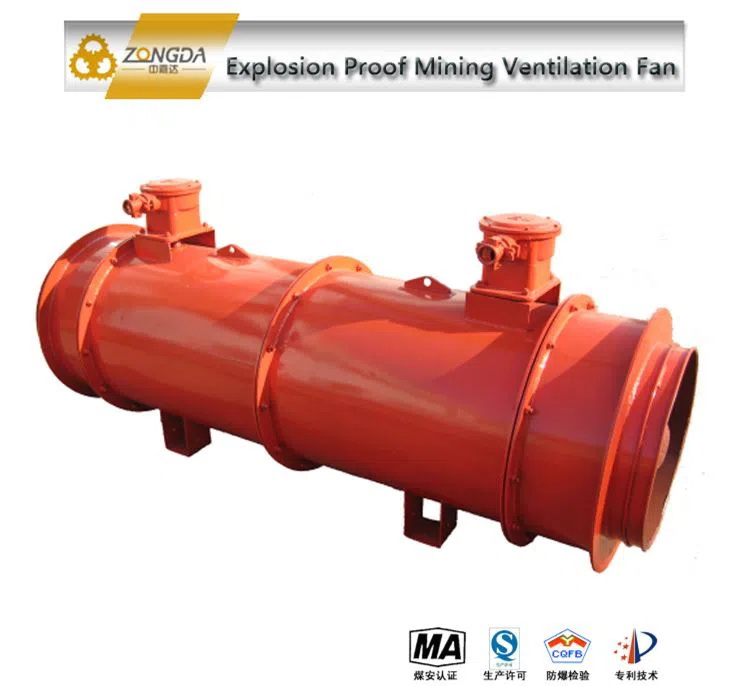

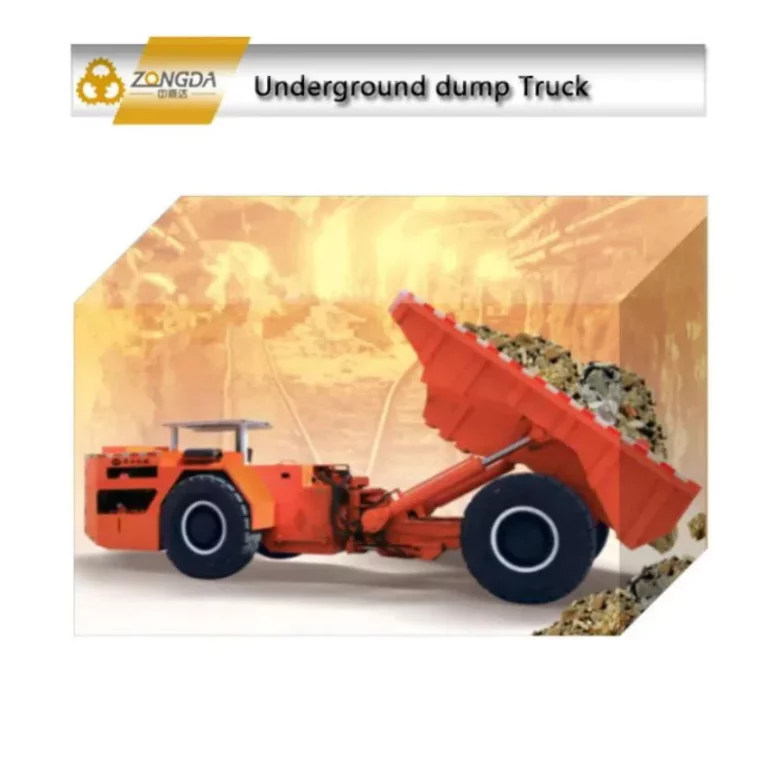

Product Range

Zongda’s extensive product range includes advanced fans, air circulation systems, and auxiliary equipment specifically designed for underground mining tunnel ventilation. The company focuses on producing energy-efficient ventilation solutions that not only comply with international safety standards but also promote environmental sustainability. By leveraging the latest technologies and materials, Zongda’s products enable mining operators to maintain optimal air quality and meet regulatory requirements effectively. This holistic approach ensures that Zongda’s offerings are well-suited to address the challenges faced by the mining sector.

Industry Impact

The impact of Zongda Mining Equipment Co., Ltd. on the industry is notable, as its innovations have led to improved ventilation systems across multiple mining operations. By prioritizing safety and efficiency, Zongda continuously contributes to enhancing working conditions for miners while simultaneously driving operational cost savings for mining companies. The company leverages its expertise to educate industry stakeholders on the importance of well-designed ventilation systems, stressing the role of robust ventilation infrastructure in promoting safety and compliance. As the demand for efficient and safe mining practices grows, Zongda’s influence and contributions will likely play an essential role in shaping the future of underground mining tunnel ventilation standards.