Underground mining operations continually evolve, resulting in significant advancements in technology and equipment. Central to these developments are the underground loaders and LHD (Load-Haul-Dump) vehicles that are instrumental in enhancing productivity and efficiency in mining operations. With the advent of new innovations in spare parts for these machines, mining companies can expect to achieve better performance, adhere to environmental regulations, and improve operator safety. This article discusses transformative trends in underground loader technology and highlights the latest innovations in LHD spare parts, as well as an overview of Zongda’s role in this domain.

Transformative Trends in Underground Loader Technology

Enhancements in Performance and Efficiency

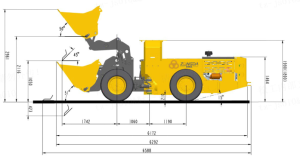

The latest advancements in underground loaders have focused on improving overall performance and efficiency. Manufacturers are integrating more powerful engines and sophisticated transmission systems that enable loaders to operate at higher speeds and with greater operational flexibility. These innovations not only enhance productivity by reducing cycle times but also optimize fuel consumption, allowing for more sustainable operations in underground environments. Advanced hydraulic systems have come to the forefront, providing loaders with the force required to handle heavy material loads while maintaining the precision needed for tight spaces.

Emission Reduction and Environmental Compliance

As global awareness around sustainability grows, underground loaders are being manufactured with a keen focus on reducing emissions and complying with environmental regulations. Innovations include engines that utilize cleaner-burning fuels and advanced exhaust treatment technologies that minimize hazardous emissions. The integration of electric-drive systems in some models also contributes to a substantial reduction in greenhouse gases. By implementing such technologies, mining companies can align their operations with contemporary environmental standards, ultimately contributing to a more sustainable future.

Advanced Safety Features for Operator Protection

Operator safety remains paramount in underground mining, leading to the implementation of advanced safety features in underground loaders. Innovations such as improved cab design, enhanced visibility systems, and integrated sensor technologies have been developed to better protect operators. Features like collision avoidance systems and real-time monitoring of operational conditions serve to mitigate risks associated with underground environments. Additionally, ergonomic advancements address operator comfort, which can significantly reduce fatigue and enhance overall safety during lengthy operations.

Latest Innovations in LHD Spare Parts

High-Durability Materials and Coatings

LHD spare parts are witnessing innovations in materials and coatings that enhance their durability and longevity. The use of advanced composites and specialized alloys can withstand the harsh conditions of underground mining, extending the lifespan of components such as buckets and frames. Innovations include protective coatings that resist wear and corrosion, minimizing the need for frequent replacements. By investing in high-durability spare parts, operators can reduce downtime and maintenance costs, leading to more efficient mining operations.

Smart Diagnostics and Predictive Maintenance Technologies

The implementation of smart diagnostics and predictive maintenance technologies in LHD spare parts represents a significant leap in operational efficiency. Utilizing sensors and IoT technology, these systems monitor equipment performance in real-time. Data-driven insights allow for early detection of potential failures, enabling proactive maintenance before issues escalate. This not only reduces the risk of unexpected downtime but also supports better asset management, aligning perfectly with the modern trend of maximizing operational efficiency in the mining industry.

Energy-Saving Hydraulic Systems

Innovations in energy-saving hydraulic systems for LHD vehicles have transformed their operational capabilities. New hydraulic technologies, such as load-sensing systems and variable-speed drives, allow for more efficient energy consumption. These systems adjust hydraulic flow according to the workload, ensuring that energy is not wasted. As a result, mining operations can achieve optimal performance while keeping operational costs in check. The environmental benefits of reduced energy consumption align with the industry’s push toward more sustainable practices.

Zongda: Pioneer in Underground Mining Equipment

Overview of Zongda’s Product Offerings

Zongda has established itself as a leader in the underground mining equipment sector, offering a comprehensive range of products that include advanced underground loaders and LHD vehicles. Their equipment is designed to meet the specific needs of the mining industry, combining innovation with reliability. Through continuous improvements in design and functionality, Zongda’s product offerings cater to various operational requirements, ensuring that clients receive optimal solutions tailored to their mining conditions.

Commitment to Research and Development

A key component of Zongda’s success is its unwavering commitment to research and development. The company invests heavily in innovative technologies to enhance the performance of its equipment and spare parts. By collaborating with industry experts and conducting extensive market research, Zongda stays at the forefront of emerging technologies. This proactive approach enables them to introduce cutting-edge solutions that advance the capabilities of underground loaders and LHDs, solidifying their reputation as a pioneer in the sector.

Customer Support and Customized Solutions

Zongda understands the unique challenges faced by mining operations, which is why they prioritize customer support and provide customized solutions. The company offers a range of services, including technical support, training, and tailored spare parts management, ensuring that clients can maintain optimal performance. By fostering strong relationships with their customers, Zongda not only addresses immediate operational needs but also contributes to the long-term success of their clients in the highly competitive mining sector.

Challenges and Future Directions in Underground Loader and LHD Spare Parts Industry

Addressing Component Longevity In Harsh Environments

Despite the advancements in materials and technologies, the underground loader and LHD spare parts industry still faces the ongoing challenge of component longevity. As operational conditions become increasingly challenging due to deeper mining and harsher environments, manufacturers must prioritize the development of parts that not only meet current durability standards but invariably exceed them. Finding solutions that mitigate wear and degradation while balancing costs will be crucial. Research into hybrid materials and advanced coatings holds promise; however, it will require an adaptive approach by suppliers to maintain relevance in a competitive market.

Continuous Evolution in Compatibility Standards

The evolution of compatibility standards presents another challenge for the underground mining sector. As new technologies emerge—such as smart sensors, IoT integration, and energy-efficient systems—ensuring that these components can seamlessly interface with previous models, older machinery, and various manufacturers becomes crucial. Establishing industry standards that facilitate compatibility will streamline operational upgrades while extending the life of existing equipment. Stakeholders including manufacturers, operators, and regulatory bodies must work collaboratively to drive these standards forward for the benefit of the entire underground mining landscape.

Future-Proof Technologies for Sustainable Mining Operations

Looking ahead, the focus on sustainability in underground operations demands that spare parts developers take an innovative approach to technology. Future-proof solutions that leverage renewable energy sources, enhance recyclability, and reduce waste generation will likely gain traction. Technologies such as electrification and automation are expected to play pivotal roles in transforming mining operations into more sustainable ventures. Collaborations among mining companies, technology developers, and environmental agencies will be essential for creating a mining ecosystem that is not only economically viable but environmentally responsible.

Partnering with Zongda for Cutting-edge Solutions

Expertise in Tailored Mining Equipment Solutions

Zongda stands out as a leader in providing innovative solutions for underground mining applications. Their commitment to understanding the unique needs of mines has positioned them as an ideal partner for operators seeking tailored equipment solutions. Zongda works diligently to design spare parts that align with the specific operational profiles of their clients, ensuring enhanced performance and longevity. By leveraging their deep expertise in mining equipment, Zongda crafts solutions that drive efficiency and productivity while minimizing the total cost of ownership for operators.

Ongoing Support and Maintenance Services

In addition to their high-quality products, Zongda emphasizes the importance of ongoing support and maintenance services as part of their offering. Their dedicated team provides comprehensive support that includes training for operators, installation guidance, and real-time assistance during operations. This proactive approach not only facilitates the optimal use of equipment and spare parts but also contributes to a culture of safety and continuous improvement in mining facilities. Zongda’s commitment to its customers extends far beyond the sale, fostering long-term relationships that enhance operational success over time.