Overview of Underground Mining Wheel Loaders

Definition and Functionality

An underground mining wheel loader is a heavy-duty piece of equipment that operators use in tight spaces within the walls, or walls and ceilings, of an underground mine. Front-end loader that is used for loading and unloading in open mining areas also for movement of material from stock area to the belt conveyors. They also help to improve productivity due to their fast loading as they can easily enter through confined spaces of the underground mining environment. The flexibility these loaders offer makes them ideal for working in the demanding conditions found underground, where consistent productivity is essential.

Importance in Mining Operations

In that regard, underground mining wheel loaders are an incredible boon to the efficacy of most mining operations. They play an important role in carrying materials to and from isolated locations, which would otherwise have been labor-intensive and dangerous. This allows them to process high volumes of material rapidly, speeding up production cycles. On top of that, wheel loaders use is very beneficial to the mining sector with respect to efficient resource extraction and hence optimized return on investment.

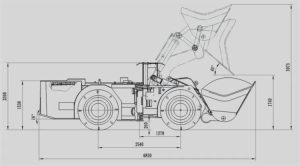

Key Components and Features

Purpose-built underground mining wheel loaders consists of some common parts that help in improving their productivity. These are things like strong hydraulics for loading, durable frame to work on bad working surfaces and special tires to give better grip on difficult terrain. Beyond this, the lower profile designs mean they work perfectly in confined ceiling spaces, yet maintain stability during use. The integration of high-end technologies also instantaneously empowers these machines to carry out intricate tasks with accuracy and quickness.

Operational Efficiency and Productivity

Load Capacity and Performance Metrics

One of the primary advantages of underground mining wheel loaders lies in their exceptional load capacity. Most models are designed to carry several tons of material in a single trip, significantly reducing the number of cycles required to complete a job. Performance metrics such as cycle time and loading speed are crucial indicators of efficiency, with modern wheel loaders achieving impressive rates that enhance overall productivity. These performance characteristics are a direct result of ongoing innovations in engineering and design, tailored specifically for underground mining applications.

Maneuverability and Adaptability in Confined Spaces

Underground mining wheel loaders have to be both productive and maneuverable, but not at the expense of one or the other. This makes them ideal for use in confined spaces where larger vehicles would not be possible. Their ability to make sharp turns and handle narrow tunnels allows front end loaders easy access in otherwise difficult-to-reach locations where the most valuable deposits are frequently found. And the machine’s adaptability is boosted by features like its articulated steering, which allows it to pivot on a dime and rotate as much as 180 degrees – no need for large-scale modifications of mine design.

Impact on Operational Costs

Using an underground mining wheel loader can lower operational costs significantly over time. In this way the labor required and time spent on each task is significantly decreased by means of these machines that streamline material handling. In addition to this, their overall endurance and high-performance capacity result in lower maintenance costs and fuel sales. All these savings also help mining operations be more competitive and economically viable, actually reducing the overall downtime by performing better and with greater reliability.

Technological Advancements

Automation and Remote Control Capabilities

Underground mining wheel loaders are being increasingly automated due to technological progress. This enables these systems to run autonomously or with minimal human intervention for safer operation in dangerous underground environments. Remote control functionality also supports operating the loaders at a safe distance to enhance both safety of personnel and effectiveness of use. The move is transforming the way mines work, opening a new age of amplified efficiency and safety.

Integration with Other Mining Technologies

Underground mining wheel loaders must be merged with a variety of other mining technologies to improve its operational features. This is includes compatibility with haulage systems, allowing loaders that can be integrated with a conveyor belt or other transport method so no manual handling of the materials is needed. Additionally, real-time data and monitoring systems increase the collaborative efficiency of mining machinery as it provides a medium to track better production metrics and predictive maintenance. The coupling of different technologies helps mining to operate in a frictionless way.

Compatibility with Haulage Systems

If your operation uses haulage systems, compatibility with the output is key to get maximum operational throughput. Those wheel loaders for underground mining are designed with features that make them easy to integrate into the transport method you currently use. This compatibility helps cut down on the necessary equipment and streamlines the material from extraction points to processing locations. Loaders, greatly minimized transitional delays and thus support an un-interrupted and continuous rhythm in the production.

Real-Time Data and Monitoring Systems

The integration of real-time data in addition to monitoring systems with the underground mining wheel loaders promotes better decision making and reduces liabilities as well. They measure performance metrics and give operators the tools to adjust operations based on real-time data. Moreover, it empowers predictive strategies to enable preventive maintenance before machines fail permanently and prevent tools from losing their lifespan.

Safety Considerations

Safety Features and Ergonomics

Underground mining wheel loaders offer top-line safety features, ensuring the machinery meets the requirements to be used in these operations. It includes protective system for advanced operators to reduce the dangers involved in driving heavy machinery through confined spaces. Ergonomic designs help to keep operators comfortable and prevent them from getting tired, which is important during long shifts in order for maintaining focus. The inclusion of safety features is consistent with other efforts to improve worker safety in environments that can be harsh.

Operator Protection Systems

Operator protection systems are vital components of underground mining wheel loaders, offering shielding from potential hazards. Features such as ROPS (Roll-Over Protective Structures) and FOPS (Falling Object Protective Structures) ensure that operators are safeguarded during adverse conditions. Enhanced visibility systems, including cameras and proximity sensors, help operators prevent accidents by providing awareness of their surroundings. These protective measures are essential for fostering a safe working environment.

Enhanced Visibility and Control Systems

Underground mining wheel loaders provide greater visibility and control for improved safety and operational efficiency. These can include improved lighting, mirrors and cameras that collectively enable operators to have a clear view of the work area. This visibility is especially important in low-light environments such as those that are common to underground work. Along with ergonomic controls, these attributes allow the operator to maintain control of the loader confidently and precisely.

Compliance with Mining Safety Standards

Underground mining wheel loaders must adhere to stringent mining safety standards set by regulatory bodies. Compliance measures include regular inspections, certifications, and incorporating safety protocols throughout the design and operational processes. Staying abreast of these standards is crucial for not only meeting legal requirements but also ensuring the safety and well-being of all personnel involved in mining operations. The commitment to compliance enhances the overall integrity of mining operations and promotes a culture of safety.

Maintenance and Longevity

Regular Maintenance Practices

For such an important piece of equipment, it is essential that underground mining wheel loaders are properly maintained so that they will function over a longer period for you. Daily maintenance should comprise of fluid levels, tire pressure, and hydraulic system checks. Operators also need to check the loader bucket and attachments for regular wear and damage, as any problems will limit efficiency and exasperate down the line. Regular servicing should be scheduled, this way any problems are caught before they cause unexpected downtime during production.

Common Issues and Troubleshooting Tips

Despite their robust design, underground mining wheel loaders may face specific common issues that can impact their operational efficiency. For instance, hydraulic system failures can significantly reduce functionality, often stemming from leaks or air in the lines. Routine monitoring can help identify these problems early. Additionally, monitoring engine performance can reveal issues such as overheating or unusual noises, indicating the need for immediate attention. Clear troubleshooting guidelines provided by manufacturers can aid operators in addressing these common concerns, ensuring that loaders remain effective and reliable in various underground conditions.

Recommendations for Prolonging Equipment Lifespan

There are several practical steps that can be taken in order to help extend the lifespan of underground mining wheel loaders. By having a good lubrication schedule, it can prevent wear and tear on moving parts allowing for better movement. Also, frequent operator training develops good practices towards the correct operations and handling of equipment which in turn reduces misapplication. Using real replacement parts during maintenance and repairs maintains compatibility and reliability while avoiding performance. Lastly, use of telematics systems to aid equipment usage monitoring for data-informed decisions when it comes to maintenance schedules and operational efficiency.

The Zongda Mining Loader: A Closer Look

Introduction to Zongda’s Product Line

Zongda has established itself as a prominent player in the mining equipment industry, particularly with their line of underground mining wheel loaders designed for challenging subterranean environments. Founded on a commitment to innovation and quality, Zongda has continuously evolved its product offerings to meet the needs of modern mining operations. Their loaders are engineered with cutting-edge technology that enhances both safety and productivity, making them valuable assets for mining companies globally. This commitment to excellence is evident in the various models available, which cater to a range of operational demands.

Brief History of Zongda in the Industry

Zongda started its journey decades ago as a small manufacturing setup and today it stands as proud brand in circuit of underground mining equipment. As brand known for its R&D efforts, Zongda is one of the pioneers in loader technology and is at the leading edge of industry trends. Operationally, they continually refine their design based on stakeholder feedback and have worked extensively with mining operators and engineers to ensure that the technology meets the operational requirements of modern mining. The story is not only a turning point in the history of Zongda, but more importantly reflects the adherence to professionalism over the car production in China by Zongda.

Overview of Product Range

Zongda offers a series of customized underground mining wheel loaders to suit various applications in the field. Its lineup ranges from compact models suitable for narrow tunnels to larger loaders capable of significant throughputs, and all are easily configurable for various mining environments. Their loaders feature powerful hydraulics, improved visibility and so on, making it integral to the choice of construction companies along with mining industries for its added safety features. In addition, Zongda provides customized solutions for customers, and allows them to choose the most suitable equipment in view of other operational requirements.

Unique Selling Points of Zongda’s Loaders

Innovative Design Elements

One of the distinguishing characteristics of Zongda’s underground mining wheel loaders is their innovative design. Focused on optimizing performance and safety, these loaders feature low-profile designs that allow them to operate efficiently in confined spaces typical of underground mining. Moreover, Zongda integrates advanced robotic welding technology in the manufacturing process, ensuring structural integrity and durability that can withstand harsh mining conditions. Other design innovations include enhanced ergonomic controls, which improve operator comfort and control efficiency, leading to better overall equipment performance.

Customer Support and After-Sales Service

Zongda prides itself on delivering exceptional customer support and after-sales service, which are critical components of its comprehensive product offering. Their dedicated support team ensures that operators have access to training and resources, boosting the effective use of equipment. Furthermore, the availability of spare parts and maintenance solutions enhances customer satisfaction and operational continuity. By fostering strong relationships with clients, Zongda positions itself as a trusted partner in optimizing mining operations and addressing any challenges that may arise.