Understanding Underground Mining Trucks

Definition and Importance

Underground mining trucks, a heavy-duty vehicles built for extreme conditions are vital in the mining sector. They’re designed to move heavy loads underground which is where regular vehicles might not work. As a result, the need for effective transportation solutions continues to grow which elevating underground mining trucks to something that simply cannot be without. This is the key to the movement of men and materials, leading to increased productivity and safety in mining operations.

Key Features That Enable Superior Performance

Structural Robustness

Underground mining trucks are built for maximum structural strength. They are built with high-strength materials that can handle the extreme forces and stresses present in underground mines. They also include sturdier chassis and heavy-duty wheel systems for added stability and endurance. This reliability sector retains the power and assures that underground mining trucks can continue to up under the finest tasks.

Advanced Technology Integration

Today, more advanced technology goes into the design of underground mining trucks, and there are plenty that have been designed using state-of-the-art technology to ensure maximum performance with minimum impacts on safety. As an example, hydraulic systems provide the ability to steer and lift, which gives better maneuverability and control. Moreover, real-time monitoring systems are also getting used to overview performance parameters, thus allowing preventive maintenance, and ensuring less idle time. These innovations facilitate rough terrain traversing while upholding high safety standards for underground mining trucks.

Handling Harsh Conditions Seamlessly

High Temperatures and Humidity Resistance

Due to extreme temperatures and the high humidity of underground mining environments, vehicle performance can be affected. However underground mining trucks are designed to withstand these extreme conditions. Items like dedicated cooling mechanisms and enclosures keep sensitive components safe from heat and dampness. This resistance facilitates the smooth functioning of the trucking operations in an adverse climate.

Maneuvering in Confined Spaces

Trucks will, however, face a major challenge in underground mining with the narrow and enclosed spaces they must navigate. Underground mining trucks with an articulated frame in the center and a small turning radius are highly maneuverable. The clever design provides the ability of these vehicles to turn and perform work in narrow aisles. Furthermore, their low-profile design assists them in reaching zones that would be unreachable to typical vehicles thereby enhancing operational flexibility.

An overview on Qingdao Zongda Machinery Co., Ltd

We are a trusted manufacturer of underground mining trucks in China. Qingdao Zongda Machinery Co., Ltd is a pioneer in this area. We develop (rail-less) mining equipment precisely for all types of extensive underground work, as is the case with the ZDT210 Underground Mining Truck: robust enough for multiple intensive operations in the same area. We are committed to safety and performance, but we also strive to bring innovation based on advanced technology into our products that meet the requirements of underground coal conditions. We demand a commitment to service and innovation to assure customer satisfaction. By utilizing strong associations and an impressive management structure, we provide great value while guaranteeing the long-term viability of our equipment.

Our many underground mining products help improve operational efficiency and safety across the globe. Our machines are not limited to trucks alone as we offer a complete solution with Personnel carriers, Loading Equipment, etc., so it is our quality of machinery and robust build along with its reputation that goes out to the market with every unit sold. We give the mining industry what it needs for success today with an eye on where technology is leading tomorrow.

Unquestionably, underground mining trucks constitute the foundation for efficient mining operations. Couple this with their unique construction, high-tech integration, and ability to withstand extreme conditions and it becomes clear that they are crucial in ensuring the success of any mining venture. These trucks still somehow continue to meet the underground mining challenges, whether it be hauling ore or getting people around.

Efficient Operations in Challenging Terrains

Underground mines face many difficulties and require vehicles that can operate under these extreme environments. This is where underground mining trucks come into play, designed specifically to handle such situations efficiently. Its design highlights top performance on several various terrains, overcoming steep gradients and uneven surface obstacles. Their ability to operate continues to become more efficient thanks in part, to the integration of advanced technologies that enable these spacecraft to transport materials and personnel effectively even under the most challenging environments.

Superior Traction Systems

Their traction systems are one of the most important features of underground mining trucks. So the trucks are fitted with wheels that have high, narrow tires designed to enhance traction when driving through wet or uneven surfaces. These traction systems are usually multi-surface, meaning they can work for both rock and dirt which is common with underground locations. Furthermore, these trucks employ high-end differential locking to achieve optimal power distribution across the wheels, allowing them to traverse more difficult terrains. These systems are designed to keep the efficiency of mining operations very high under adverse working conditions.

Load Capacity and Stability

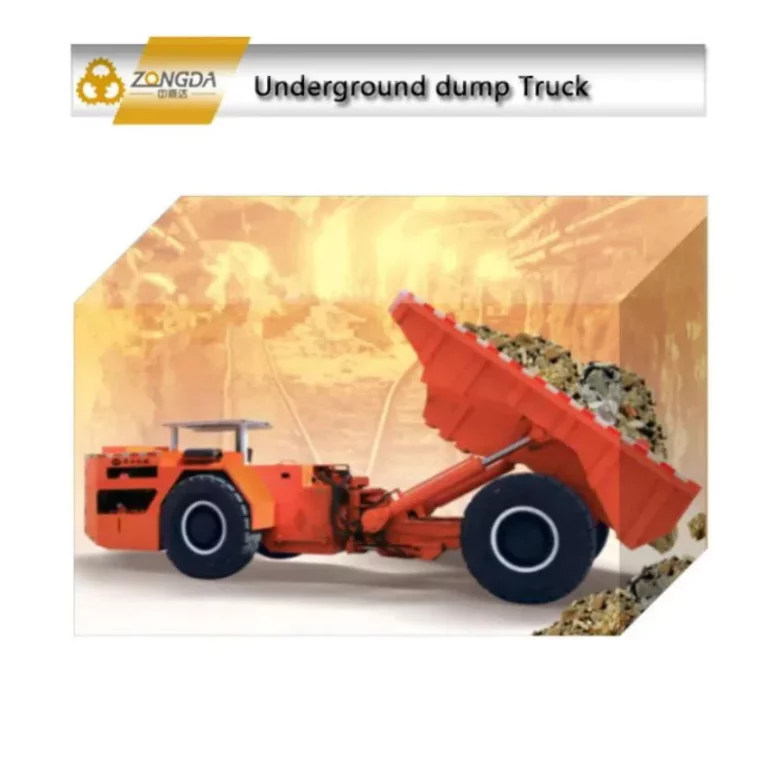

The load capacity and stability of underground mining trucks play a vital role in ensuring efficient operations. Trucks like the 12-ton Underground Mining Dump Truck (KU-12) are specifically designed to handle significant weights while maintaining stability. Constructed with robust frames and reinforced structures, these vehicles can carry heavy loads without compromising safety. Furthermore, larger trucks such as the 70 Ton Underground Mining Dump Truck HOWO 6X4 Dumper Truck provide even greater capacity while ensuring a stable center of gravity. Their design minimizes the risk of tipping, allowing for the safe transport of materials through winding and narrow tunnels.

12ton Underground Mining Dump Truck (KU-12)

The 12-ton Underground Mining Dump Truck (KU-12) exemplifies how design and functionality combine to meet the unique demands of underground mining. It boasts a rated load capacity of 12 tons, ensuring that it can meet most material transport needs on site. The truck incorporates a hydraulic control system, which enhances both safety and comfort for operators. With a maximum climbing capacity of 25% and a turning radius of 4500 mm, the KU-12 maneuverability is impressive, allowing it to negotiate tight spaces without difficulty.

70-Ton Underground Mining Dump Truck HOWO 6X4 Dumper Truck

The 70 Ton Underground Mining Dump Truck HOWO 6X4 Dumper Truck represents a larger scale of operations. This truck is built for heavy-duty tasks and has a fully hydraulic control system that ensures superior operational efficiency. It prioritizes both safety and comfort during transport while maintaining its load-carrying capability. The design integrates various safety features that allow it to operate in harsh conditions while providing stability and reliability during operations.

Innovations Paving the Future of Underground Mining Trucks

Ongoing advancements in technology and design are mistakenly shaping the future of underground mining trucks. The focus of several companies is on such eco-friendly solutions and smart enhancement utilities for better efficiency and sustainability of mining barnet. Mining firms are now concentrating on creating green solutions and improving smart operations to boost mining efficiency and sustainability.

Eco-friendly Solutions

The expedited focus towards sustainable practice is driving eco-friendly underground mining trucks. These innovations emphasize emissions reduction and fuel efficiency, making strides toward global sustainability objectives. Vehicle architectures can comply with regulations while still having the performance desired by lowering emissions by using things that have been returning for lower emissions. For instance, the use of sophisticated exhaust purification systems allows for to reduction of the pollution impact during work hours thus making a more environmentally friendly mining process.

Smart Operations

The underground mining trucks are fitted with smart technology to improve productivity. For example, GPS tracking and real-time telemetry systems give operators important information regarding vehicle performance, location, and maintenance requirements. This technology enables more effective fleet management, which helps the operators coordinate movements between vessels easily and reduces idle times as well. Predictive maintenance tools also guarantee that operations do not get interrupted and safety standards are not compromised by anticipating failures before they happen. Mining companies can achieve optimal resource partition by using smart operations, increasing productivity, and a competitive advantage over other companies in the industry.

Overall, the innovations made to underground mining trucks can mitigate some of the challenges currently plaguing your local operation while also laying the ground for improved efficiencies down the road. Underground mining trucks are designed with high traction systems, high load capacity, and various technologies to conquer harsh environmental conditions with fastness and sustainability. The mining industry can keep its productivity and environmental obligations in check as long as it continues to champion sustainable solutions and smart operational approaches.